About

Welcome to the Opportunity

A New Nimble and Adaptive

Chemical Processing and

Manufacturing Company

Extraction and processing of lithium is highly complex and is very particular to the chemistry of each solution being treated. There is significant know-how and different types of technologies that can be applied. FCL’s technology has proven the capability to not only extract lithium from solution at recovery rates of +99% but also produce a clean lithium precursor solution that is able to produce high purity lithium carbonate. FCL also has the knowledge of manufacturing lithium carbonate from either lithium sulfate or lithium chloride and its team has built several lithium plants in the USA over their careers.

There are only a few lithium refineries in the USA and capacity is limited and insufficient for the next growth stage of lithium mines in the USA. Similarly, there are many efforts to recycle lithium. It’s becoming harder to secure the know-how to manufacture lithium and even harder to secure refining capacity from USA producers and it will not get any easier in the future.

There is a need for new, nimble and adaptive lithium chemical processing companies that can meet the growing need for processing various feedstock and/or precursor raw lithium concentrates in order to supply the market with final lithium compounds. These new processing companies must compete not only in quality but in service, and be able to meet the demands of upstream and downstream industry players.

The Home of Lithium Science

Robust Business Model

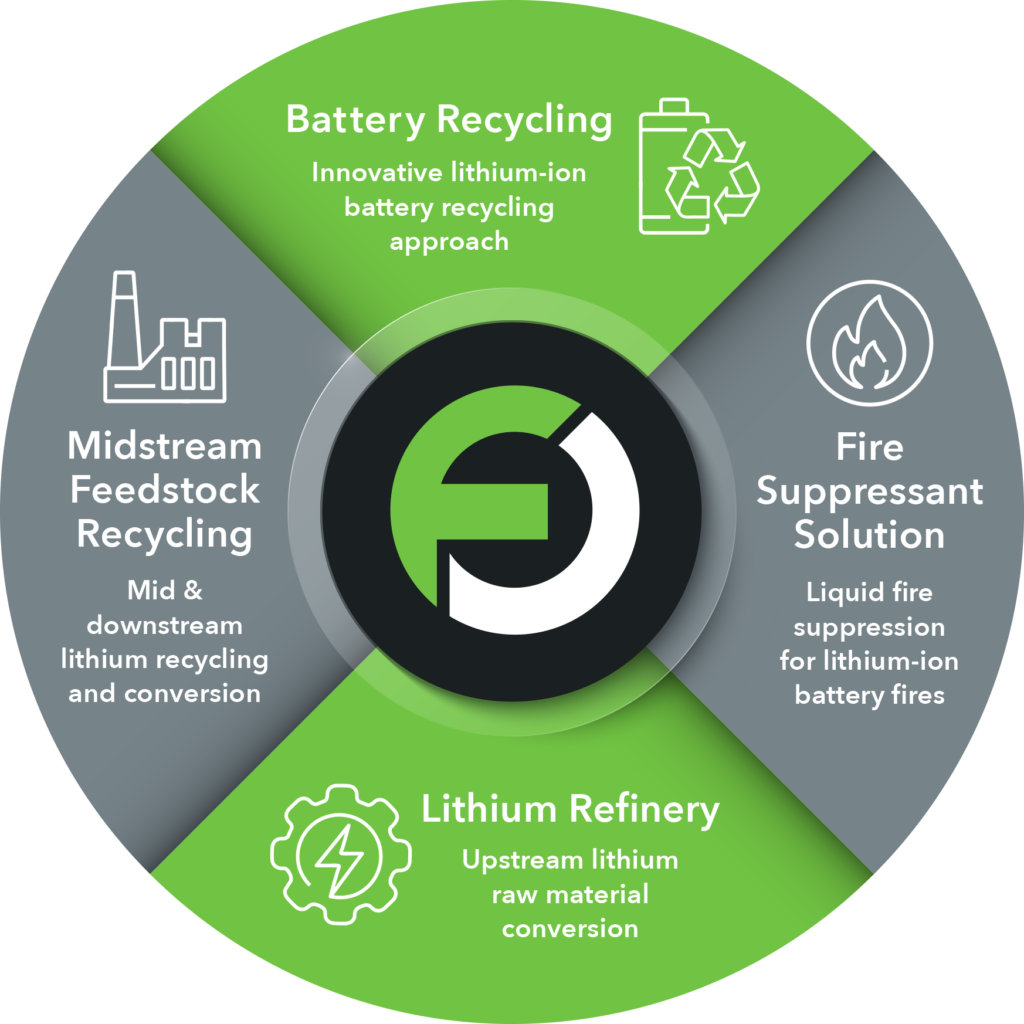

- In addition to our diversified business model of having 4 distinct feedstock sourcing potential (midstream recycling, lithium-ion battery recycling, lithium refinery and our FCL-X product), we have a fully permitted and operating lithium carbonate manufacturing plant

- Up to 2,000 t/yr capacity with ability to expand to up to 10,000 t/yr

- The newest and only greenfield capacity expansion in the North America in over two decades

- Our entire business model includes a total integrated approach of patent pending lithium technology, which includes our own proprietary fire suppressant agent (FCL-X), an absorbent production facility as well as significant infrastructure to develop our in-house fire suppressant solution production and training

What Sets Us Apart

Lithium Feedstock Sourcing – Diversified Business Lines

Midstream Feedstock Recycling

- Business is focused on chemical and manufacturing companies that utilize lithium compounds in their primary processes and have a residual lithium bearing stream

- FCL deployed of a modular demo plant to initial client

- Successfully extracted >99% of the lithium from the lithium effluent in multiple cycles and also met impurity removal targets in final product

- Subject to final agreement, will lead to proprietary modular commercial production plant build-out in early 2024

- Currently in discussion with a number of other specialty chemical companies

Lithium-ion Battery

- FCL’s uses a selective automated component separation and processing system (battery processing unit) and is focused on mitigating the three process safety risks of lithium-ion batteries recycling: discharge of batteries, hydrogen/heat generation and fluoride process/recovery

- Initial focused on LFP batteries, but also looking at other battery types and off-spec material both for battery and precursor cathode only material

- FCL has already pre-processed and disassembled spent lithium-ion batteries and successfully produced LC

- Larger scale demonstration and automation work ongoing to determine processing and economics, as well as optimize/automate methods for final extraction process for lithium and other materials

Lithium Refinery

- FCL can offer lithium extraction and lithium carbonate production expertise and there is significant interest in lithium chemical extraction and processing expertise

- Currently in initial stages of development work with Argentine brine

- Initial discussion refining precursor lithium compound into lithium carbonate (technical/battery)

Georgia, USA

The Future of Electrification

Our Focus

Georgia, USA – Prime Lithium Processing Jurisdiction

In Georgia, EV-related projects have surpassed US$20B, with OEM’s such as Hyundai Motor Group & Rivian. Battery suppliers such as SK Battery and Freyr, as well as other supply chain enablers (which include battery recyclers Ascend Elements and SungEel Recycling) are also located in the State.

Georgia has strong State-sponsored workforce training facilities, excellent education programs, and nationally ranked colleges – all providing Georgia businesses with talent to achieve success.

The State has supported consumer adoption of EVs and electrification programs. Public and private entities are offering incentives and suggesting policies to support continued growth of the electric mobility sector. Georgia is 6th in the nation for number of public EV charging stations, offering more than 1,500 individual outlets – equating to more outlets per capita than anywhere else in the Southeast. Georgia is clearly focused on the future of electrification!